Cement grinding Aids

Cement grinding aid

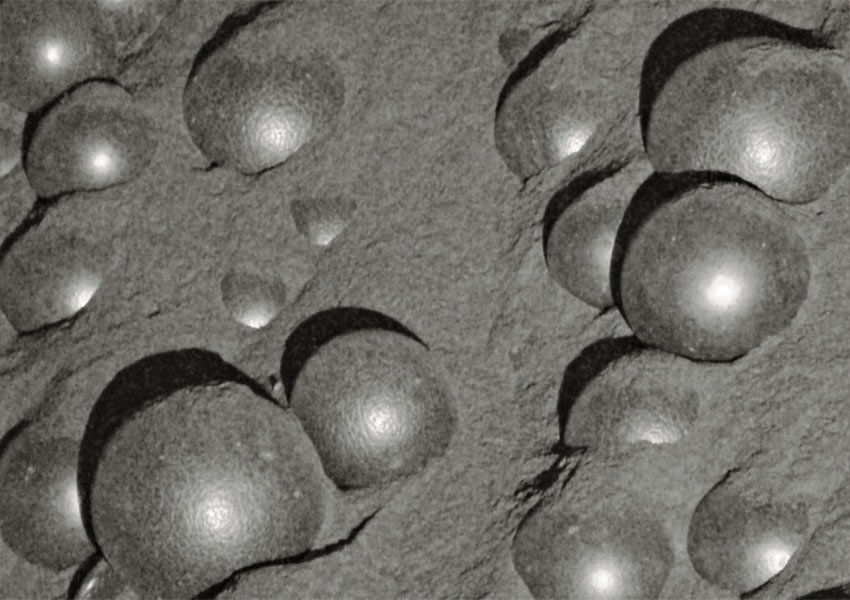

70% of the energy consumed in cement production is related to grinding and 30% of this 70% is wasted as heat. A study has shown that only 0.6% of the total energy consumption in grinding is spent on particle size reduction. In addition to the possibility of achieving higher softness, the use of grinding aids will not have a significant impact on the finished product price and will also reduce energy consumption. On the other hand, the help of grindings helps to prevent the coating of grinds balls and lining with small particles.

Pars grind’s cement grinding aid products have a high variety and the ability to provide exclusive and unique solutions for each cement factory.

In general, the benefits of pars grind cement grinding aid are:

- Increasing sales and reducing production costs by increasing production rates, increasing separator efficiency and reducing energy consumption

- Improving the quality of cement by increasing the softness and improving the size distribution of cement particles

- Improving the efficiency of concrete made from cement in water to similar cement

- Reducing maintenance costs and increasing efficiency by reducing the surface coverage of balls, linings and diaphragms with cement particles.

- Reducing the clogging of cement silos and their repair costs by improving particle size distribution, increasing separator efficiency and improving flowability.

- Reducing carbon dioxide emissions by reducing clinker consumption at the same production rate

These products are produced and presented with two main goals:

- Improving the mechanical characteristics of cement, such as short-term or long-term resistance, setting time, etc.

- Reducing the cost of cement by replacing part of the clinker with other additives such as slag, pozzolan, limestone, etc. while maintaining the quality of the cement.

Abrasion aid and cement quality improver

Wear aid of mineral powders

Abrasion aid and cement quality improver

The products that help wear and improve the quality of cement of Parsman Construction Company are provided under Pars Grind brand. They have a lot of variety and capabilities. Pars Grind’s quality improvement products improve the mechanical characteristics of cement in addition to the property of helping wear. These products are produced and presented with two main goals:

- Improving the mechanical characteristics of cement, such as short-term or long-term resistance, setting time, etc.

- Reducing the cost of cement by replacing part of the clinker with other additives such as slag, pozzolan, limestone, etc. while maintaining the quality of the cement.

The benefits of wearing and improving the quality of Pars Grind cement are as follows:

- Increasing the softness of cement.

- Improvement of particle size. distribution and removal of very fine and very large particles.

- Increasing the flowability of cement.

- Increasing the effectiveness of concrete in water to the same cement.

- Effect on hydration reactions.

- Reducing the total price by reducing the consumption of clinker in mixed cements.

Wear aid of mineral powders

The mineral powder wear aid products of Parsman Sazeh House Building Company are offered under the Pars Grind brand and can be provided for mineral powders in Asia.

Lime, talc, barite, perlite, silica, feldspar, ochre, kaolin and alumina are among the mineral powders that can be used for grinding. Meanwhile, lime or calcium carbonate is of special importance due to its wide application in various industries and also the higher softness required for it. Calcium carbonate powder is produced in different particle sizes and in some cases the particle size reaches 1 micron.

The advantages of Pars Grind products for mineral powders in Asia are as follows:

- Increase production capacity by

more than 20% without increasing energy consumption.

- Reducing energy consumption at the same production rate.

- Improvement of the granulation curve by removing very fine and very coarse particles in equal softness factor.

- Reduction of maintenance costs due to reduction of coating of pellets, silos, etc.

- Reducing the production of greenhouse gases.

- Increasing the flowability of produced powders.

Pars Grind’s wear aid products of mineral powders with a very high variety can be used for grinding all kinds of mineral powders. Some of these are as follows:

- Alumina (aluminum oxide) – Al2O3

- Barite (barium sulfate) – BaSO4

- Slaked lime (calcium oxide) – CaO

- Calcium carbide – CaC2

- Lime (calcium carbonate) – CaCO3

- Calcium silicate – CaSiO3

- Calcium sulfate – CaSO4

- Chromium oxide – Cr2O3

- Dolomite- CaMg(CO3)2

- Feldspar

- Gypsum – CaSO4.2H2O

- iron oxide

- Kaolin- Al2Si2O5(OH)4

- Limestone

- magnesium

- Magnesium hydroxide – Mg(OH)2

- Magnetite-Fe3O4

- Muscovite (mica) – KAl2(AlSi3O10)(F,OH)2

- Perlite

- Quartz (silica) – SiO2

- Rutile (titanium dioxide) – TiO2

- Talc- Mg3Si4O10(OH)2

- Zirconium dioxide – ZrO2

- Zirconium silicate – ZrSiO4